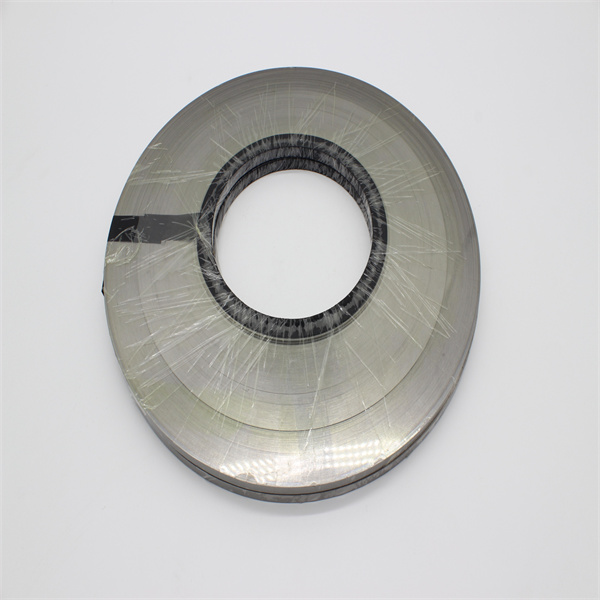

The new ultra free-cutting wire is a testament to Beijing Shougang Gitane's commitment to providing high-quality materials for its clients. The wire is designed to exhibit exceptional cutting properties, making it ideal for use in the precise manufacturing processes of ball-point pen tips. This innovation is a testament to the company's dedication to research and development in the materials industry.

The wire is manufactured using the latest technology and equipment, ensuring the highest level of precision and quality. Beijing Shougang Gitane's team of expert engineers and material scientists have meticulously designed and tested the wire to meet stringent industry standards, ensuring that it exceeds expectations in terms of performance and reliability.

By utilizing the ultra free-cutting wire in the production of ball-point pen tips, manufacturers can expect to see improvements in efficiency and productivity. The wire's ability to maintain its integrity and sharpness during the cutting process greatly reduces the occurrence of production errors and defects. Additionally, the wire's consistency and durability contribute to the overall quality and longevity of the final product.

Moreover, the ultra free-cutting wire contributes to the overall sustainability of the ball-point pen manufacturing process. Its efficient cutting properties minimize material wastage, resulting in a more environmentally friendly production process. This aligns with Beijing Shougang Gitane's commitment to sustainable and responsible manufacturing practices.

The development of the ultra free-cutting wire for ball-point pens showcases Beijing Shougang Gitane's continued dedication to innovation and excellence in the materials industry. The company's ability to identify opportunities for improvement and develop cutting-edge solutions underscores its position as a leader in the field of special alloy wires and strips.

Beijing Shougang Gitane's expertise in producing special alloy wires and strips extends beyond ball-point pen applications. The company's diverse product range includes resistance heating alloys, electrical resistance alloys, stainless steels, and spiral wires for a wide range of industrial and domestic applications. With a focus on quality, reliability, and customer satisfaction, Beijing Shougang Gitane has established itself as a trusted partner for clients seeking high-performance materials.

In addition to its product offerings, Beijing Shougang Gitane is also committed to providing exceptional customer service and technical support. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their unique needs. This customer-centric approach has earned Beijing Shougang Gitane a reputation for excellence in the industry.

As Beijing Shougang Gitane continues to push the boundaries of material engineering and innovation, the company remains dedicated to delivering best-in-class products and services to its clients. The development of the ultra free-cutting wire for ball-point pens is just one example of the company's ongoing commitment to excellence and advancement in the materials industry.

In conclusion, Beijing Shougang Gitane New Materials Co., Ltd.'s development of the ultra free-cutting wire for ball-point pens exemplifies the company's dedication to innovation, quality, and sustainability. With a rich history of producing specialized alloy wires and strips, the company continues to lead the way in material engineering and sets a high standard for the industry as a whole. As Beijing Shougang Gitane looks ahead to the future, its commitment to excellence and customer satisfaction ensures that it will remain a key player in the materials industry for years to come.